Classification and Application Cases of Pulse Laser Cleaning Machine (Ⅰ)

The new generation of laser cleaning can replace many traditional cleaning methods.

Compared with traditional cleaning methods, laser cleaning has many advantages.

1. Laser cleaning is not only environmentally friendly and precise, but also efficient and easy to automate. It is regarded as a disruptive industrial cleaning technology.

2. Laser cleaning was used in the early days to clean precise ancient buildings and precious cultural relics. Over time, its application gradually expanded to the industrial field. In the past 20 years, mature large-scale applications have been carried out in multiple fields.

In 2016, the first pulse laser cleaning machine of Alien Cleaner came out. In 2018, the laser cleaning machine still stayed at the 100-watt level. But starting from 2019, fiber pulse laser technology has broken through 1000W. In 2020, the power of Alien Cleaner fiber laser for cleaning will exceed 2000W.

In just 6 years, China's laser cleaning industry as a whole has broken through the following technologies:

1. Integrated collaborative control board system

2. Focus tide pool system

3. Edge light control system

4. Beam homogenization and shaping system, anti-shake, high tolerance and other technologies.

Out of the consideration of the world's environmental protection concept. China also pays more attention to the development of laser cleaning technology.

Alien Cleaner has 18 years of experience in R&D and production of laser equipment. The appearance and cleaning gun head of our pulse laser cleaning machine are all independently developed and designed. We can also adjust according to different industries and product needs. Recently, many customers and friends have come to consult us. So next, a professional engineer will introduce to you what are the applications of pulse laser cleaning machines. Interested friends can continue reading.

Depending on the spot pattern. Laser cleaning machines can be divided into two types:

1. Single-mode (Gaussian light) cleaning machine

2. Multi-mode (flat top light) laser cleaning machine.

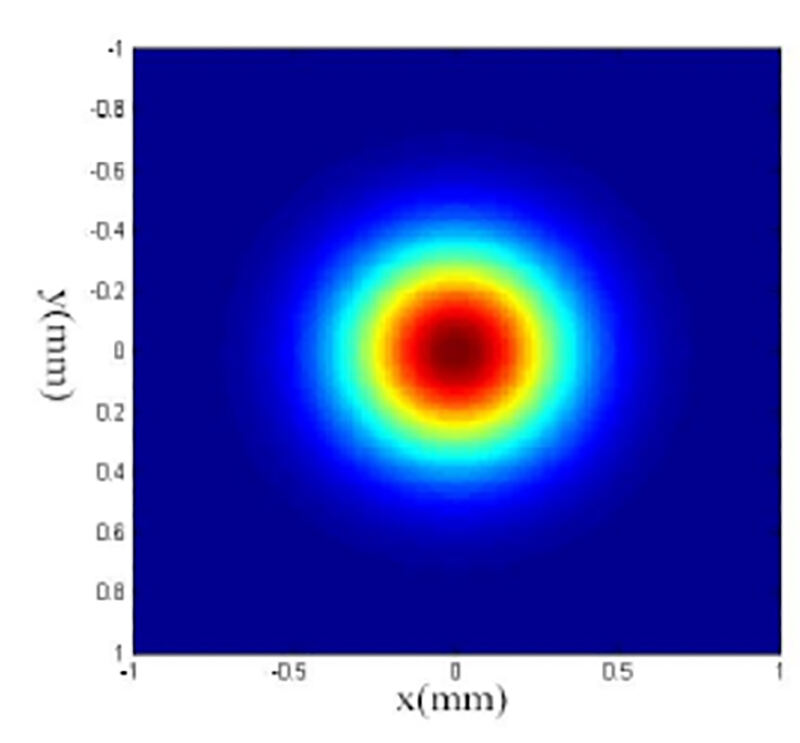

Single mode is also called Gaussian light

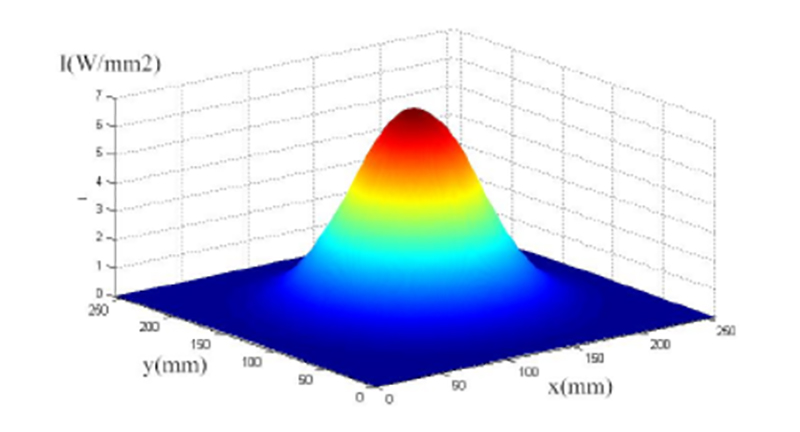

Single-mode lasers have a thinner core and better beam quality than multimode. Its energy distribution is Gaussian, with the highest energy density in the middle. The 3D map is in the shape of a pointed round mountain.

Two-dimensional light intensity distribution of single-mode laser

Three-dimensional light intensity distribution of single-mode laser

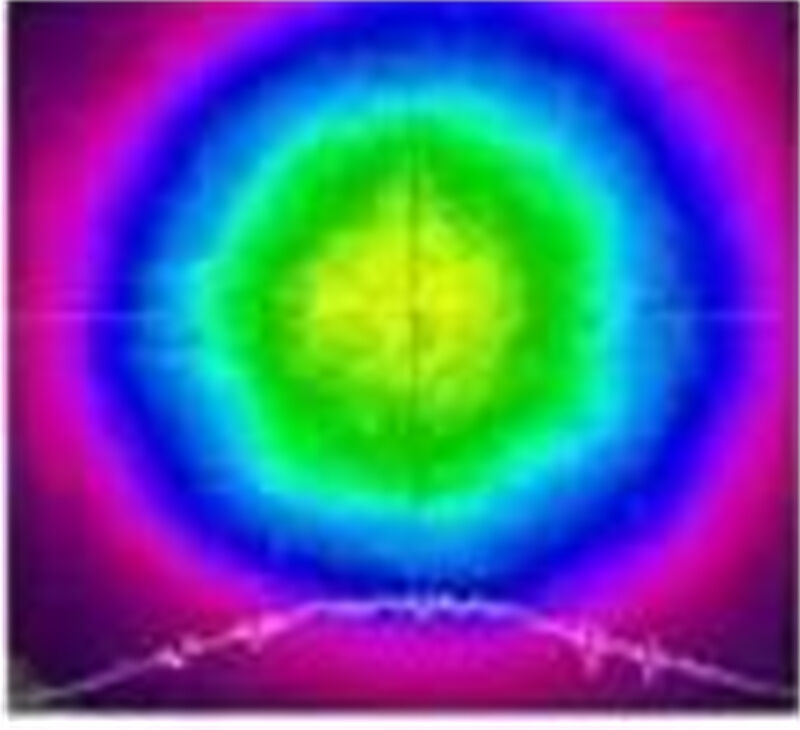

Multimode is also called flat top light

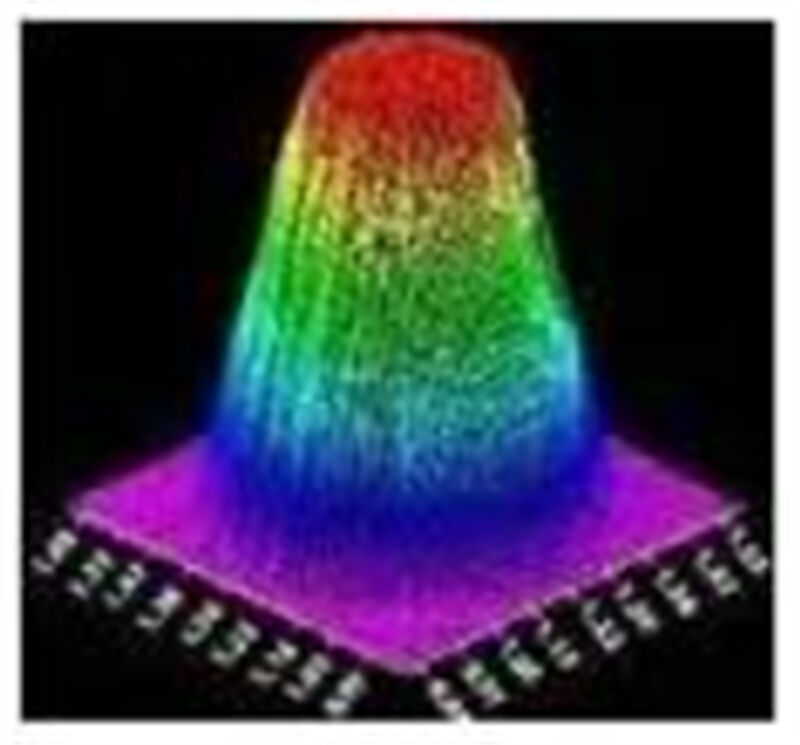

Multimode lasers have thicker cores. Its beam quality is worse than that of single mode. It's like an upside-down cup. The energy distribution from the edge is steeper than that of the single-mode spot. The three-dimensional image is viewed from the angle degree. Multimode is much steeper than singlemode.

Two-dimensional light intensity distribution of multimode laser

Three-dimensional light intensity distribution of multimode laser

Gaussian light and flat top light cleaning effect display

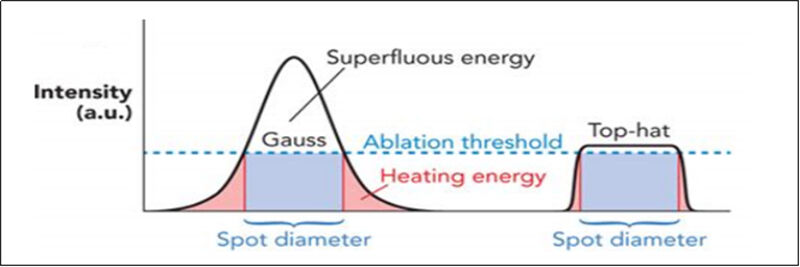

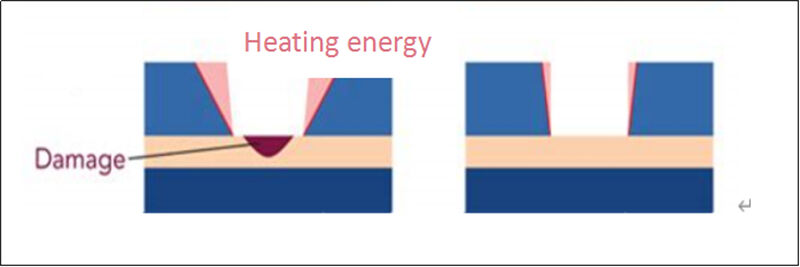

Figure 1 Gaussian light (left) and flat top light (right)

The Gaussian beam has high energy density in the center and low energy density at the edge, so it is easy to clean

It is easy to cause the energy density in the center to be greater than the damage threshold of the matrix, and it is easy to damage the matrix. The edge is below the cleaning threshold for contaminants, resulting in no contaminant removal at the edge. Top-hat beams have the same energy density at the center and at the edges. Therefore, it can better solve the problem generated by Gaussian beams. It also does little damage to the matrix.

Application:

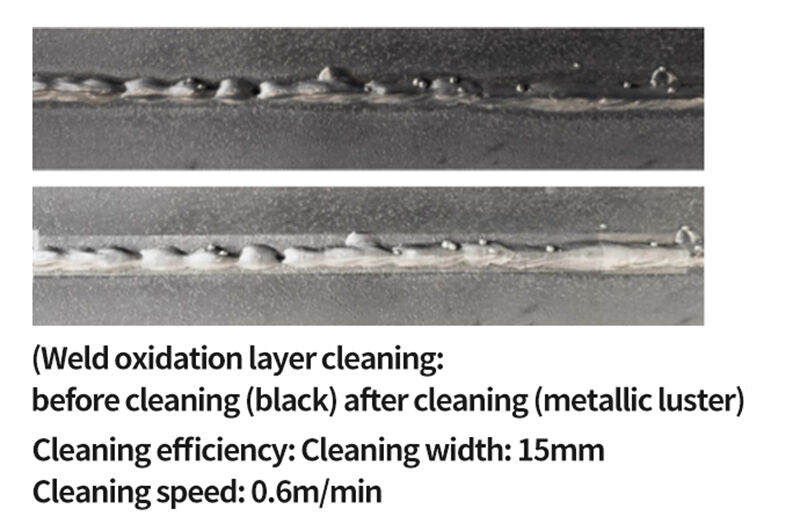

The following is a comparison chart of cleaning cases of Alien Cleaner ALCM100 pulse laser cleaning machine:

Rust removal is an important application for pulsed laser cleaners. In industrial production, metal products are often affected by factors such as oxidation and rust. As a result, problems such as spots and oxide layers appear on the surface.

Traditional rust removal methods usually require the use of chemicals or mechanical equipment. It is not only inefficient, but also easily pollutes the environment. The pulse laser cleaning machine uses the high energy of the laser beam. It can quickly peel off the rust on the metal surface, thereby restoring the smoothness and beauty of the metal.

As can be seen, the laser cleaned areas are in stark contrast to the uncleaned rust. The cleaned place is like new, even brighter.

Application:

The following is a comparison chart of cleaning cases of Alien Cleaner ALCM200 pulse laser cleaning machine:

Application scenario:

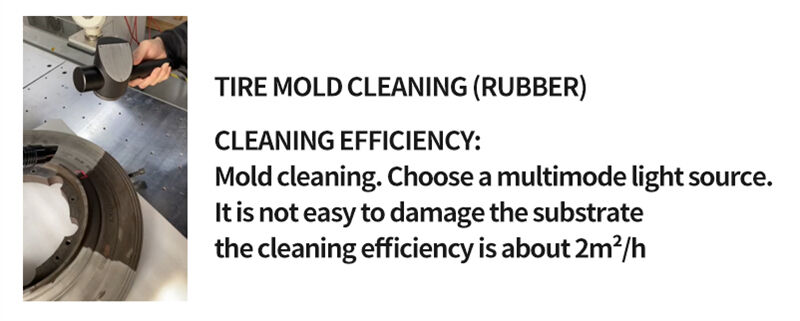

Tire moulds have strict requirements on cleaning conditions. Because clean molds are essential for high-quality products. It will directly affect the quality level of the tire after molding. Therefore, it is required not to cause damage to the surface of the mold when using laser cleaning. The roughness of the mold surface cannot be changed. And after cleaning, the color of the mold surface is evenly presented as the primary color of the metal.

paint removal

The following is the cleaning case of Alien Cleaner ALCM200 pulse laser cleaning machine:

ALCM200 pulse laser cleaning machine uses high-energy pulse laser beam. It heats and evaporates the paint on the mechanical surface instantly. It can be peeled off quickly. Compared with traditional cleaning methods, ALCM200 has many advantages.

Traditional paint removal methods usually use chemical solvents or mechanical grinding. These methods are not only inefficient, but also easily cause damage to the object to be cleaned.

Whereas ALCM200 can remove paint without damaging the substrate. It maintains the integrity and performance of mechanical equipment. Second, since the laser beam is non-contact, it can clean small or intricate areas that are hard to reach. Ensure thorough cleaning. In addition, ALCM200 also has the characteristics of high efficiency, fast speed and energy saving. It can greatly improve production efficiency and save costs.

The process of paint removal with a pulsed laser cleaner is very simple. First, place the mechanical equipment to be cleaned on the workbench of the washing machine. And adjust the focus and power of the laser beam. Then, aim the laser beam at the area to be cleaned and press the start button. Under the irradiation of the laser beam, the paint will be evaporated and peeled off quickly. Simultaneously generated fumes and waste are sucked away. The whole cleaning process can be controlled by observing the cleaning effect and adjusting parameters. To ensure the thoroughness and quality of cleaning.

In addition to paint removal, laser cleaning can also be applied in other fields. In the automotive industry, laser cleaning can be used to clean and purify automotive surfaces. It can remove stains and oil stains on the surface of the car, etc. Gives the car a new look.

The above is the application introduction of 100W and 200W pulse laser cleaning machine, and its cleaning efficiency. Next, we will continue to update the application cases of other power pulse laser cleaning machines. stay tuned.

EN

EN

AR

AR BG

BG CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LT

LT SL

SL UK

UK VI

VI HU

HU TH

TH TR

TR AF

AF MS

MS BE

BE MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY LB

LB