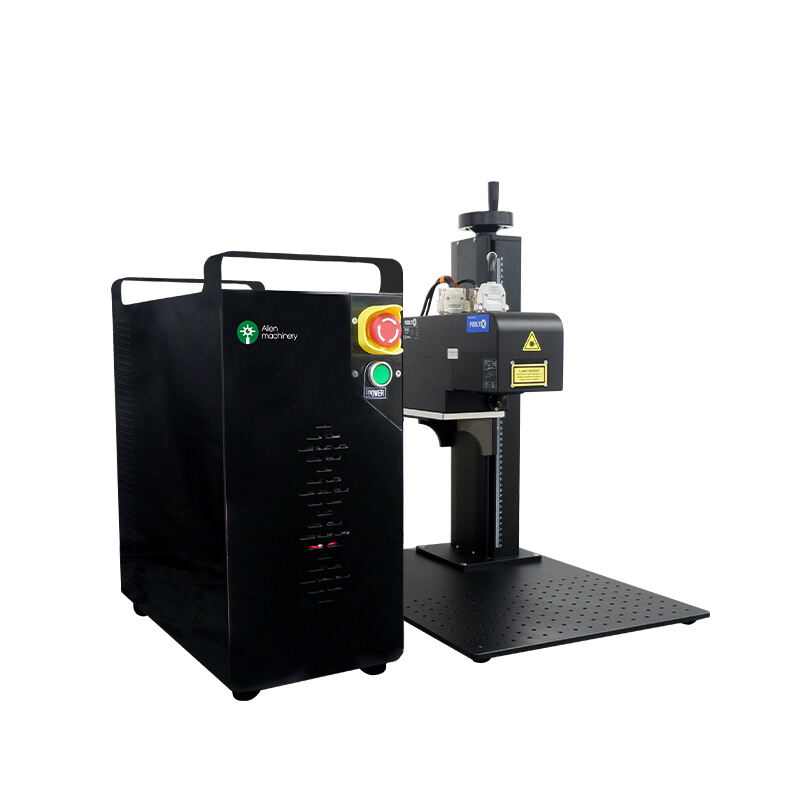

3D laser marking machine

What is a 3D laser marking machine?

Nowadays, laser marking machine has become one of the essential equipment in modern production line. Among them, the 3D laser marking machine has been widely used in industry and personal use. So, what is a 3D laser marking machine? Today, engineers from Alien Machinery came to chat with you.

3D laser marking machine is a high-precision equipment capable of marking, cutting and engraving in three-dimensional space. It uses the laser beam to mark, cut and engrave the surface of the workpiece. It has the advantages of high efficiency, high precision and high stability. At the same time, it can also realize the free creation and processing of various patterns, characters and images. To meet the different needs of users.

The working principle of the 3D laser marking machine: it uses the laser beam to locally heat the surface of the workpiece with high energy. Melt or vaporize the surface of the material. Thus forming the desired marking or engraving. The laser beam of the 3D laser marking machine has good quality and high energy density. Fine processing can be completed in a short time, and high-speed and high-precision processing effects can also be achieved.

The application of 3D laser marking machine?

3D laser marking machines are widely used in various industries. What are the specific ones, let me analyze them in detail below.

1. In automobile manufacturing: 3D laser marking machine can engrave, cut and process auto parts. Make parts more refined and beautiful;

2. In medical device manufacturing: 3D laser marking machine can mark and engrave the surface of the device. Make devices easier to identify and manage.

3. In the personal field, 3D laser marking machines are gradually being widely used. For example, jewelry makers can use 3D laser marking machines to engrave, mark and design jewelry. To enhance the value and aesthetics of jewelry. Artists can use 3D laser marking machines for engraving and cutting to create more exquisite works of art.

In short, 3D laser marking machines have important application value in modern production lines and personal fields. It provides users with more choices and convenience. With the continuous development of technology and the continuous expansion of applications. It is believed that the application range of 3D laser marking machines will become wider and wider. Bring more surprises and convenience to people.

What are the types of 3D laser marking machines?

With the continuous development of science and technology. 3D laser marking machines are widely used in industrial manufacturing and medical industries. It can also be seen in aerospace and other fields. 3D laser marking machine is a device that uses laser beams for processing, marking and engraving. In the field of 3D printing, 3D laser marking machine is also an indispensable tool. The following will introduce the types and characteristics of 3D laser marking machines.

1. Optical fiber 3D laser marking machine

A fiber laser marking machine is a device that uses a fiber laser as a laser source. It is efficient, reliable and durable. Fiber laser marking machines are suitable for all metals. There are also engraving and engraving of some non-metallic materials, such as plastic, glass, and ceramics. Its main advantage is the high quality of the laser beam. Small beam diameter and high energy density. It can achieve high-precision, high-speed marking and engraving effects.

2. CO2 3D laser marking machine

A CO2 laser marking machine is a device that uses a CO2 laser as a laser source. It is suitable for imprinting and engraving on non-metallic materials. Such as common wood and paper, as well as cloth and leather. The main advantage of the CO2 laser marking machine is that its laser beam can be absorbed by most non-metallic materials. It can achieve high-speed, high-precision marking and engraving effects.

3. UV 3D laser marking machine

UV laser marking machine is a kind of equipment that uses ultraviolet laser as laser source. It is suitable for all kinds of precision non-metallic materials. Materials such as glass and ceramics, as well as plastics. The main advantage of the UV laser marking machine is the short wavelength of its laser beam. It has a high energy density. Therefore, high-precision, high-speed marking and engraving effects can be achieved.

Different laser marking machines are suitable for different materials. They can all meet the needs of different fields. In the future, with the continuous development of technology, the application range of 3D laser marking machines will continue to expand.

3D laser marking machine application industry?

Now 3D laser marking machine application industry is more and more extensive. The following is the analysis of the engineers of Alien Machinery:

1. The principle of 3D laser marking machine

3D laser marking machine is a high-precision engraving equipment. Its working principle is to process, cut or mark objects with a laser beam. It is a non-contact processing method. The laser beam can complete the processing of the object in a very short time. Therefore, the production efficiency can be greatly improved.

2. Advantages of 3D laser marking machine

3D laser marking machines have many advantages over traditional cutting equipment. First of all, its processing accuracy is high, and it can realize high-precision processing of objects. Secondly, the operation is simple, and the processing of the object can be completed only through computer control. In addition, it can realize the processing of various materials. Including metals and non-metals and plastics, etc. It has high applicability.

3. The application industry of 3D laser marking machine

(1). Electronic industry

The electronics industry is one of the most important application industries for 3D laser marking machines. Due to the high precision requirements of electronic products. It can realize the precision machining of electronic components in the electronics industry. Can improve production efficiency and production quality.

(2). Automobile manufacturing industry

The automobile manufacturing industry is also one of its application industries. 3D laser marking machine can realize the processing of auto parts.

(3). Medical device manufacturing industry

The medical device manufacturing industry has very high requirements on the precision and quality of products. 3D laser marking machine can realize high-precision processing of medical device manufacturing products. Improve product quality and safety.

(4). Jewelry manufacturing

3D laser marking machines are also widely used in jewelry manufacturing. Jewelry manufacturing requires the processing of a variety of materials. 3D laser marking machines can realize high-precision processing of various materials. Improve the efficiency and quality of jewelry manufacturing.

The application industry of 3D laser marking machine is very extensive. Can be used in electronics industry and automobile manufacturing industry. There are also various fields such as medical device manufacturing and jewelry manufacturing. It is believed that the application range of 3D laser marking machines will become more and more extensive.

3D laser marking machine configuration

The core component of the 3D laser marking machine is the laser. Parameters such as the power and wavelength of the laser will directly affect the performance of the 3D laser marking machine. Lasers currently on the market mainly include CO2 lasers, fiber lasers and semiconductor lasers. Among them, CO2 lasers are suitable for cutting and engraving large-area materials. Fiber lasers are suitable for marking and engraving small items. Semiconductor lasers are suitable for marking and engraving metal materials.

1. The control system of the 3D laser marking machine is also very important.

The control system mainly includes computer, laser control card and motion control card. The computer is responsible for controlling the operation of the entire system. The laser control card is responsible for controlling the switch and power of the laser. The motion control card is responsible for controlling the motion of the machine. The performance of the control system will directly affect the accuracy and stability of the 3D laser marking machine.

2. The optical path system of the 3D laser marking machine also needs to be configured.

The optical path system mainly includes laser head, lens, mirror, scanning mirror and so on. The laser head is responsible for focusing the laser beam into a small spot. Mirrors are used to adjust the diameter and shape of the laser beam. Mirrors and scanning mirrors are responsible for directing the laser beam exactly where it is needed.

3. The workbench of the 3D laser marking machine also needs to be properly configured.

The table needs to have functions such as height adjustment and rotation. To accommodate materials of different shapes and sizes. At the same time, the surface of the workbench also needs to have a certain protective performance. In order to avoid unnecessary damage to the workpiece.

In summary. The configuration of the 3D laser marking machine needs to comprehensively consider the laser and the control system, as well as the optical path system and the workbench. Only under the premise of reasonable configuration, the 3D laser marking machine can exert the greatest benefits. Alien Machinery only produces high-quality 3D laser marking machines within a reasonable range. If necessary, please contact online customer service and serve you at any time.

EN

EN

AR

AR BG

BG CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LT

LT SL

SL UK

UK VI

VI HU

HU TH

TH TR

TR AF

AF MS

MS BE

BE MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY LB

LB