1000W 2000W 3000 Fiber Laser Derusting Machine Laser Cleaning Machine

| Place of Origin: | Shandong China |

| Brand Name: | Alien Cleaner |

| Model Number: | ALCL1000/ALCL1500/ALCL2000/ALCL3000 |

- Overview

- Description

- Application

- Specifications

- Advantage

- Video

- Inquiry

- Related Products

| Minimum Order Quantity: | 1 |

| Price: | USD 4600-10900 |

| Packaging Details: | Our machines are packed in fumigation-free wooden crates. There are 3 layers of packaging in total. For the outside, we use fumigation-free wooden crates. In the middle, the machine is covered with foam to protect it from shaking. The inside of the machine is wrapped in a waterproof plastic bag. |

| Delivery Time: | 15 Day |

| Payment Terms: | TT/West Union/Payple/LC/Cash etc. |

| Supply Ability: | 100 sets per month |

Description

This is our fiber optic continuous laser cleaning machine, which has the advantages of good cleaning effect, high efficiency and high degree of automation. Handheld laser cleaning head, light and convenient, suitable for long hours of work. The power of the machine can be selected from 1000W/1500W/2000W/3000W, providing users with more cleaning solutions.

Application

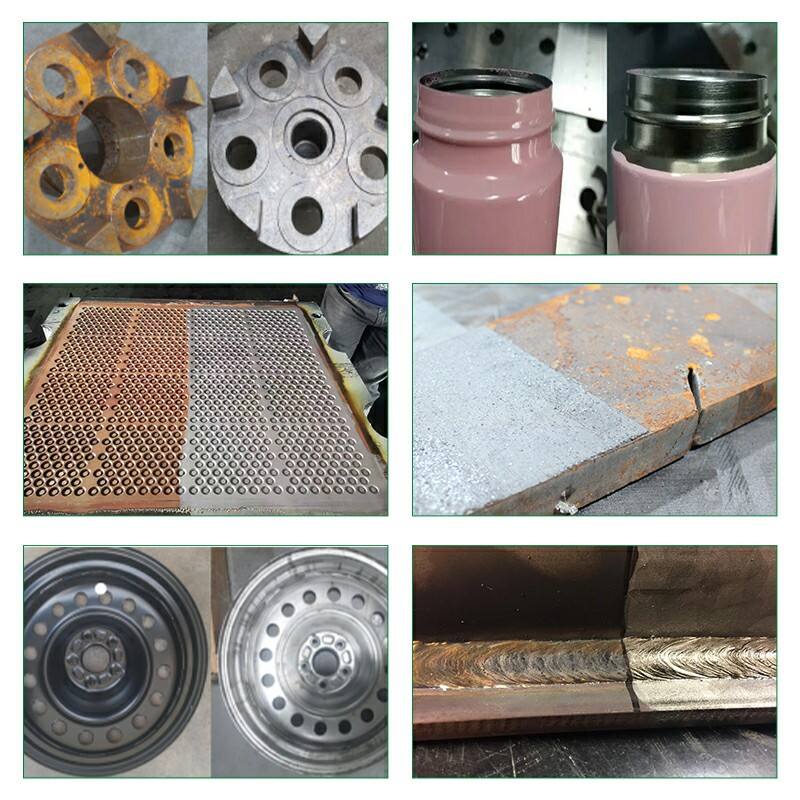

A continuous laser cleaning machine is a device that uses laser technology to clean surfaces and remove pollutants. Continuous laser cleaning machine can be used to clean rust, paint, coating, oxide, dirt, etc. on the surface of metal materials.

Specifications

| Model | ALCL1000/1500/2000/3000 |

| Laser source | MAX/Raycus/BWT Fiber Laser Source |

| Laser Power | 1000W/1500W/2000W/3000W |

| Fiber cable L | 10M |

| Wavelength | 1080nm |

| Clean speed | ≤40 M²/Hour |

| Scann speed | 0-14000mm/s |

| Cooling method | Water cooling |

| Working voltage | 0.5KW/AC220V/50Hz(option) |

| Laser frequency | 10-20KHZ |

| Voltage | 220V/2P for 1000W and 1500W 380V/3P380V/3P for 2000W |

| Temperature | 5-40℃ |

Advantage

1. No need to use chemical solvents, good environmental protection.

2. The cleaning process is non-contact, with little damage to the substrate.

3. The machine has a long service life and is maintenance-free.

4. The cleaning process is highly controllable, suitable for different materials and cleaning requirements.

EN

EN

AR

AR BG

BG CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LT

LT SL

SL UK

UK VI

VI HU

HU TH

TH TR

TR AF

AF MS

MS BE

BE MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY LB

LB