1500w 2000w 3000w lithium battery laser welding machine

| Place of Origin: | Shandong China |

| Brand Name: | Alien Machinery |

| Model Number: | ALW1500/ALW2000/ALW3000 |

- Overview

- Description

- Application

- Specifications

- Advantage

- Inquiry

- Related Products

| Minimum Order Quantity: | 1 |

| Price: | USD 16000-21000 |

| Packaging Details: | Our machines are packed in fumigation-free wooden crates. There are 3 layers of packaging in total. For the outside, we use fumigation-free wooden crates. In the middle, the machine is covered with foam to protect it from shaking. The inside of the machine is wrapped in a waterproof plastic bag. |

| Delivery Time: | 15 Day |

| Payment Terms: | TT/West Union/Payple/LC/Cash etc. |

| Supply Ability: | 100 sets per month |

Description

This is a gantry-type galvanometer laser welding machine, which accurately focuses the laser beam on the welding point by adjusting the angle and speed of the galvanometer to achieve high-precision, high-speed, and stable welding process. It can be used to weld components such as battery slices, battery covers, and connecting bars inside the battery.

Application

Ⅰ.Application of laser welding in battery industry:

1.Laser welding battery sheet: In the battery manufacturing process, it is necessary to weld the battery sheet, electrode sheet, connecting sheet and other components. The galvanometer laser welding machine can achieve high-precision battery sheet welding through the focusing and accurate positioning of the laser beam, ensuring the stability of the welding point and the reliability of the battery performance.

2.Laser welding battery pack: In battery assembly, the galvanometer laser welding machine can be used to weld battery components, such as the connection between battery modules, the fixing of insulating sheets, etc.

3.Laser repairing batteries: During the battery manufacturing process, some welding defects or connection problems may occur. A galvo laser welding machine can be used to fix these problems and improve the quality and performance of the battery.

Ⅱ.Application of laser welding in new energy:

1.Electric vehicle manufacturing: Cars are an important means of transportation in our lives. In the manufacture of electric vehicles, the galvanometer laser welding machine can be used to weld battery components, electric drive systems and key components of the body structure to improve the safety and reliability of electric vehicles.

2.Solar cell manufacturing: A solar cell is a device that uses solar energy to convert it directly into electricity. In the solar cell manufacturing process, the galvanometer laser welding machine can be used to connect the metal wires between the cells to ensure the effective conduction of current and high-efficiency energy conversion.

3.New energy equipment manufacturing: In the manufacturing process of power generation equipment, galvanometer laser welding machines can also play an important role. It can be used to weld and connect complex parts of equipment, ensuring efficient operation and reliability of equipment.

Specifications

| Model | ALW1500/ALW2000/ALW3000/ |

| Laser source | MAX |

| Pulse width | 0.1-20ms |

| Laser power | 2000W |

| Frequency | 0-100HZ |

| Wavelength | 1064nm |

| Solder joint size | 0.2-3.0mm |

| Protective gas | N2 gas |

| journey | 1000x600x600x300/400mm |

| GPS | CCD |

| cooling method | water cooling |

| Cooling system | air cooling |

How to choose a suitable galvanometer laser welding machine?

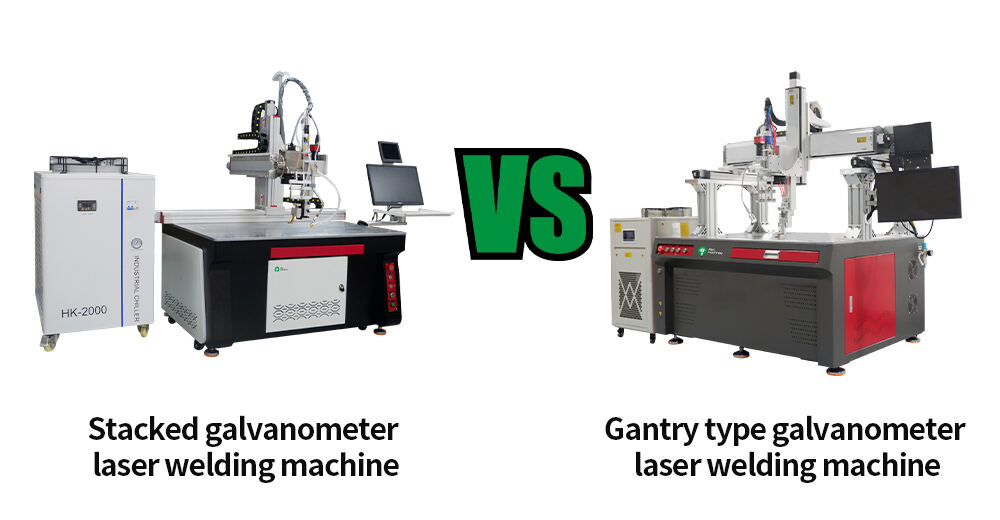

| Comparison of Alien Machinery gantry type and stacked galvanometer laser welding machines | |

| Advantages and disadvantages of gantry type laser welding machine | Advantages and Disadvantages of Stacked Laser Welding Machine |

Advantages: 1. Stable structure 2. Fast running speed 3. Rigidity is relatively strong 4. The stroke is large 5. Heavy load (suitable for some heavier products) | Advantages: 1. There is no limitation in space and can be applied to various large-scale products. 2. Cheap price |

Disadvantages: Price is expensive | Disadvantages: The speed is too high and it becomes shaky, and the rigidity is not enough to add a cylinder. |

According to the advantages and disadvantages of galvanometer laser welding machines, Alien Machinery gives some suggestions for your reference: If you are welding battery packs, lithium batteries, new energy batteries, etc., and the products you weld are heavier and require higher welding precision, it is recommended to use a gantry type machine. If other products are to be welded, the axis movement speed is not required to be too fast, and the superimposed structure can be used to complete the work, the price is relatively cheap, and the cost is relatively low. If you don't know how to choose, you can send us the welding materials and requirements, and we will recommend a suitable machine for you. | |

Advantage

1. High precision welding

This galvanometer laser welding machine can achieve very fine welding and is suitable for high precision welding. Especially small components, battery tabs, precision parts welding.

2. Welding speed block

Laser welding can achieve high welding speed, thereby improving production efficiency and saving costs.

3. High degree of automation

The laser head uses a motor to drive the X and Y axes. With multiple swing modes, laser welding can be integrated with automation systems to achieve a highly automated production process.

4. Welding is flexible

Laser welding can adapt to different welding needs by adjusting the laser parameters and beam shape, to meet the different welding needs of users, and has strong flexibility.

EN

EN

AR

AR BG

BG CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LT

LT SL

SL UK

UK VI

VI HU

HU TH

TH TR

TR AF

AF MS

MS BE

BE MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY LB

LB