Small Sealed Type 3030 Precision Laser Cutting Machine

| Place of Origin: | Shandong China |

| Brand Name: | Alien Machinery |

| Model Number: | ALC1000/ALC1500/ALC2000/ |

- Overview

- Description

- Application

- Specifications

- Advantage

- Inquiry

- Related Products

| Minimum Order Quantity: | 1 |

| Price: | USD 13900-21000 |

| Packaging Details: | Our machines are packed in fumigation-free wooden crates. There are 3 layers of packaging in total. For the outside, we use fumigation-free wooden crates. In the middle, the machine is covered with foam to protect it from shaking. The inside of the machine is wrapped in a waterproof plastic bag. |

| Delivery Time: | 15 Day |

| Payment Terms: | TT/West Union/Payple/LC/Cash etc. |

| Supply Ability: | 100 sets per month |

Description

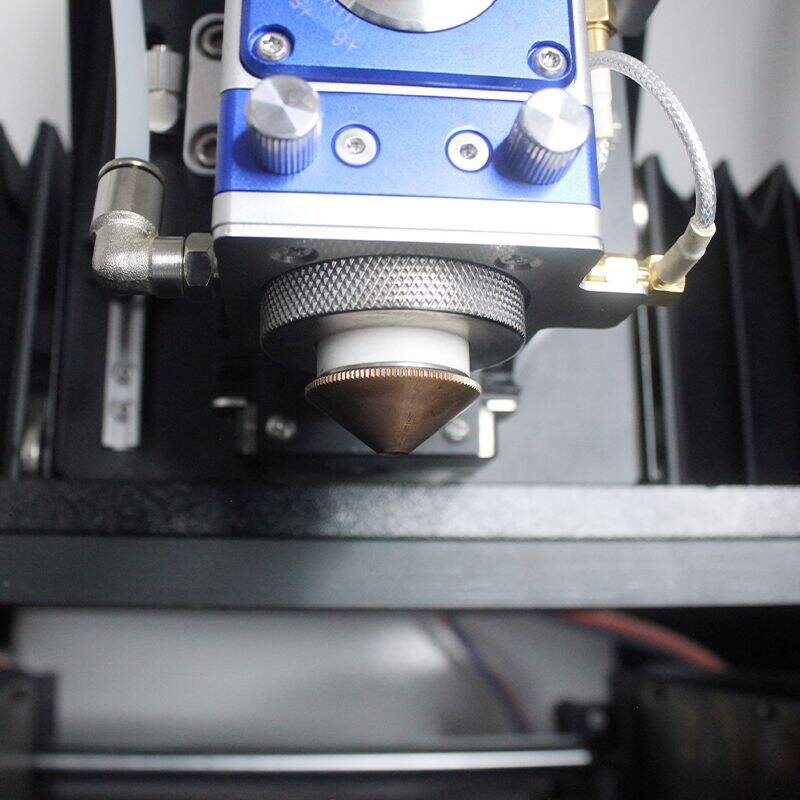

The 3030 precision laser cutting machine adopts a sealed design to prevent dust and foreign matter from entering the cutting area, and the cutting process will not affect the surrounding environment. Strong cutting stability, good quality and high precision. Equipped with a chiller, it can cool the fiber laser and QBH connector at the same time, with stable working performance and long service life.

Application

Alien CNC laser cutting machine has the advantages of high precision, high efficiency, non-contact, etc., and has a wide range of applications in the industrial field. 3030 fiber laser cutting machine can be used to cut different types of metal materials, such as steel plate, carbon steel, stainless steel, aluminum alloy, titanium alloy, etc.

Specifications

| Product model | 3030 fiber laser cutting machine |

| Work area | 300*300 (mm) |

| Fiber power | 1500W |

| Laser wavelength | 1064nm |

| Positioning precision | ±0.03mm |

| Maximum operating speed | 30m/min |

| Cutting speed | depending on the material |

| Assist gas | air, oxygen, nitrogen |

| Cooling method | Industrial circulating cooling water |

| Aiming and positioning | red glow |

| Working hours | 24H |

Advantage

1. High cutting precision

The laser cutting system is equipped with a high-precision control system, which can make minor adjustments as needed to ensure cutting quality and accuracy.

2. Non-contact cutting

Laser cutting is a non-contact cutting technology. The laser beam is directly transmitted from the equipment to the workpiece without physical contact, reducing wear and damage to the cutting material.

3. Small heat affected zone

The heat-affected zone generated during laser cutting is small, which greatly reduces the possibility of deformation and damage to the cutting material.

4. Complex shape cutting

Laser cutting is suitable for cutting workpieces of various complex shapes, including round, square, uneven contours, etc. The cutting work is flexible to meet the needs of different productions.

5. Simple operation

The staff can precisely control and adjust the cutting parameters through the computer. Stable performance, simple operation, and simple on-site drawing.

EN

EN

AR

AR BG

BG CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LT

LT SL

SL UK

UK VI

VI HU

HU TH

TH TR

TR AF

AF MS

MS BE

BE MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY LB

LB